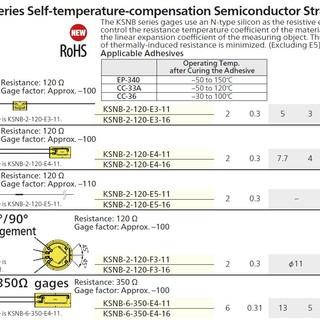

Die KSNB-Halbleiter-DMS arbeiten mit n-Silizium, dessen Temperaturkoeffizient des Widerstands vom Hersteller an den linearen Wärmeausdehnungskoeffizient des Messobjektwerkstoffs angepasst werden kann. Sie zeichnen sich durch extrem kleine Temperaturabhängigkeit ihres Widerstands aus.

KSNB – Self-temperature-compensating semiconductor strain gages

(Gage-factor: -100)

Order on request

These products are requested only from ZSE. Our employees will contact you as soon as possible with an offer.

Order on request

This product is ordered on request!

An account at myZSE gives you the opportunity to order this product directly.

Productgroups

Accessories

CC-33A-5

Instantaneous strain gage adhesive cured at normal temperature.

Operating Temperature: -196 .. 120 °C

Metals (Steel, stainless steel, copper, aluminum alloys A1050, A2024, etc.)

Plastics (Acrylate, PVC, nylon, etc.)

Composite materials (CFRP, GFRP, PCB, etc.)

Rubber

5 tubes á 2 grams

CC-36-5

- Suitable for bonding a high-elonation gage such as KFEM and KFEL at normal temperatures of 20 to 80°C

- Suitable for bonding to hard-to-bond materials such as aluminum alloy (A7075) and magnesium alloy

- High peeling resistance, high impact resistance and less aging deteriotation of bonding strength

- Strong bonding power to hard-to-bond materials

- Curing time is longer than CC-33A

- Operating Temperature: -30 to 100°C

- Metals (Steel, stainless steel, copper, aluminum alloys A1050/A2024/A7075, magnesium alloy, etc.)

- Plastics (acrylate, vinyl chloride, nylon, polypropylene, etc.)

- Composite materials (CFRP, GFRP, printed board, etc.)

- Concrete

- Mortar

- Lumber

- Rubber

Kyowa Electronic Instruments

KYOWA ELECTRONIC INSTRUMENTS CO, LTD. is a Japanese company that has been covering all core elements of industrial strain measurement technology since 1951.