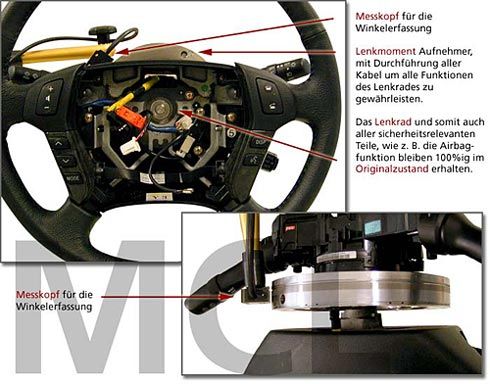

This new type of Steering Wheel Transducer has been designed for a precise measurement of Steering-moment and Steering angle applied at a Standard Steering Wheel. All function of the Standard Steering Wheel, including safety functions (per example airbag etc.) remain100% in operation.

The output signal of the moment transducer is going to be wireless transmitted and captured by a on – board DAQ (Data acquisition device). The within Steering wheel available on board power, can be as well tapped for powering the Electronic of MCL-2 components located at the Steering Wheel. Required adaptors are part of the scope of delivery. By push button control at the DAQ one can reset the moment signal to Zero. Shunt calibration can be executed by push button control located at the Steering Transducer. The Steering Angle is going to be scanned contactless by a external installed Sensor heat and captured data are transmitted via cable to the on board DAQ. The 2 trace Signal is, if required, as well available as TTL Signal. Furthermore, the Angle speed created by a Microcontroller is available at the analogue output of the DAQ. At the DAQ is as well a Zero adjust of the Steering Angle by push button control possible.

The DAQ can be delivered on demand with a installed RS-232 (9-pol. Sub-D) Interface in order to be able to read out Moment and Angle. The RS-232 Interface is due to a internally applied converter converted to a hardware USB Interface. Because of a driver the hardware USB at the Computer appears as a virtual COM Interface (VCP)

Data are available at a galvanic decoupled CAN-Bus. Set up of the CAN Interface (Identifier and Baud rate) takes place via RS-232 Interface (USB -> virtual COM).

Optional available: Software to capture data via CAN Interface in order to visualize values of figures, per example as courses of curves and back up of data as well as reproduction of data. Driver for VCP Interface and an Excel Macro for set up of CAN Interface will be delivered.