Electrical strain gages are used for high-precision stress analysis for a wide variety of components and designs and in transducer construction. A large number of strain gage types are available for this purpose. It is the user's responsibility to install them on the components to be examined, to establish the connection to suitable measuring amplifiers, to carry out and evaluate the measurements, and finally to draw conclusions about the stress and operational safety.

High-quality measurements therefore require the use of suitable strain gages as well as trained users who are able to perform proper installation, instrumentation and strain evaluation.

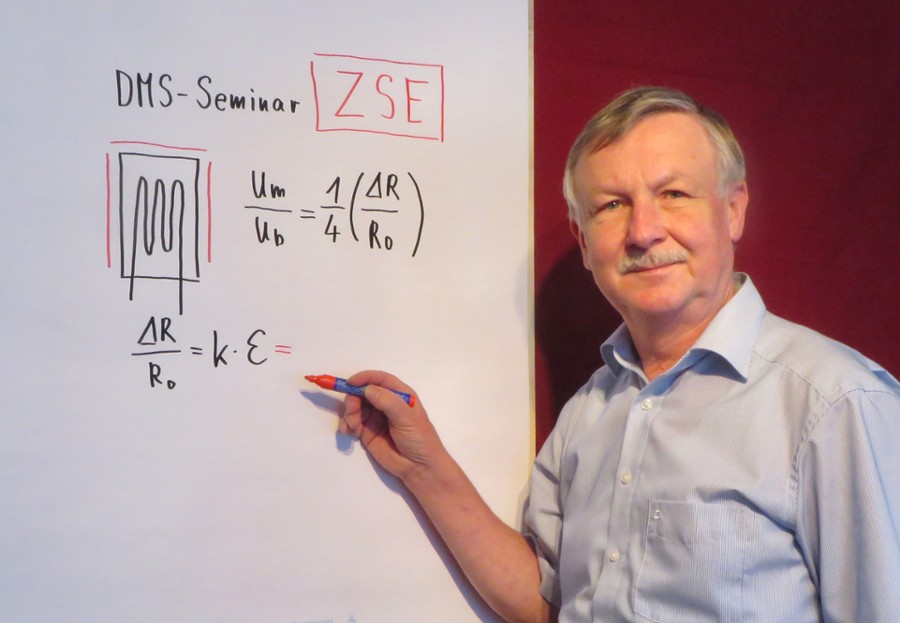

ZSE Electronic Mess-Systeme & Sensortechnik GmbH supports potential strain gage users in room and high temperature applications in selecting strain gages, accessories and amplifiers. Furthermore, ZSE offers certified training courses according to VDI/VDE guideline 2636 in the entire strain gage application area.

To the course offers