KFB – Bolt axial tension measuring gages

(Max. 50ºC)

Order on request

These products are requested only from ZSE. Our employees will contact you as soon as possible with an offer.

Order on request

This product is ordered on request!

An account at myZSE gives you the opportunity to order this product directly.

KFB - Strain Gages for Measuring Axial Tension of Bolt.

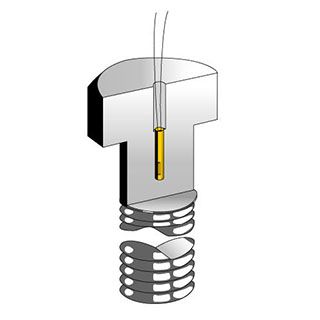

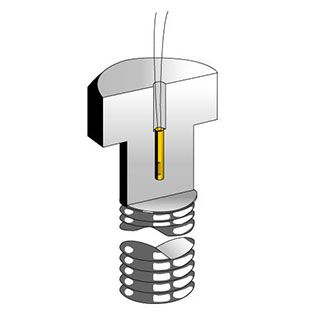

If it is difficult to bond a strain gage to the surface of a bolt for measuring the tightening stress, these gages enable the measurement by embedding into a hole, 2 mm in diameter, bored from the top head of the bolt.

Measuring screw with strain gauge for determining axial forces

For the measurement and monitoring of preload and operating forces special prepared screws which contain a strain gauge inside. ZSE offers the screws suitable for KYOWA strain gauges (KFB series) suitable for this purpose, as well as their Installation on. KYOWA has been producing this strain gage series for many years and has a field of measurement of bolt forces extensive experience of many years.

For the preparation of these strain gauges the screws must be drilled with a very precise can be provided. The cylindrical strain gauge is then glued into this hole. During operation (tightening of the screw connection, operating load), this strain gauge is the ability to measure strain (static and dynamic), from which the bolt force can be determined. Both the insertion of the bore and the preparation of the Strain gauges require special knowledge and equipment. Therefore ZSE offers the complete Preparation for a wide range of customer screws of different types and Dimensions as service to.

Example for the preparation of a M8 screw are the basic materials (screw, strain gauge), the installation sketch, instruments for cleaning of the drill hole and for filling with adhesive, as well as the prepared screw.

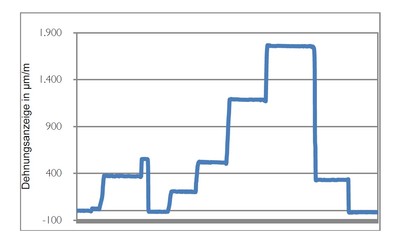

The high quality of this measuring system can be impressively confirmed by two load tests. Between thumb and forefinger, clear measurement signals can already be obtained (high resolution).

In a second test, this micrometer is tightened with different real torques preloaded. The stability of the measuring system is shown by the constancy of the measured values at load and also that after the load has been released the strain display returns to exactly zero goes back.

Specifications

- Materials Resistive element

-

CuNi alloy foil

- Materials Resistive element

-

CuNi alloy foil

- Materials Resistive element

-

CuNi alloy foil

°C

- Materials Resistive element

-

CuNi alloy foil

Bolt axial tension measuring gages

D

EP-370

For bonding gages embeddable in bolts

Request

S

EP-370

For bonding gages embeddable in bolts

- 2 types of epoxy liquid mixed,Cured at normal temperatures and by heating

- Curing: 24 hours or more at a room temperature,5 hours or more at 80 °C

- Operating Temperature: Room temp. to 50°C

- Content: 40 g (Main agent: 30 g, Curing agent: 10 g)

S

D

T-F29

Glass-epoxy soldering supports for cylindrical bolt gages.

Diameter: Inside: 2.5 m [...]

Request

S

T-F29

Glass-epoxy soldering supports for cylindrical bolt gages.

- Diameter: Inside: 2.5 mm, Outside: 6.0 mm

- 20 pcs/package

S