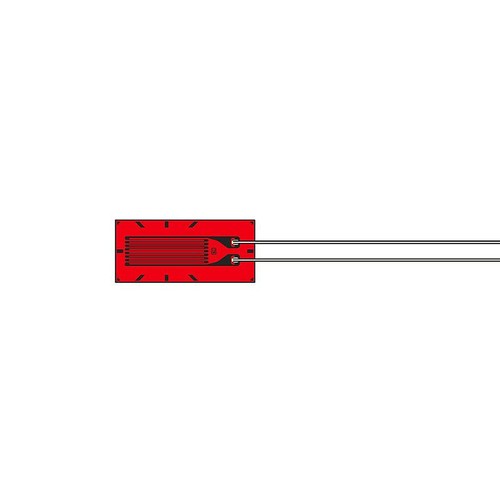

For general purpose

(350 Ohm)

Order on request

These products are requested only from ZSE. Our employees will contact you as soon as possible with an offer.

Order on request

This product is ordered on request!myZSE gives you the opportunity to order this product directly.

The new KFGS series CuNi alloy foil strain gages with the highest level performance ever.

Specifications

Nennwiderstand

350

Ω

k-Faktor

2.1

Materials Resistive element

CuNi alloy foil

Materials Base

Polyimide

Safe Temperature Range

-196 –

150

°C

Compensated Temperature Range

10 –

100

°C

Strain limits at normal temperature

5

%

Operating temperature in combination with major adhesives after curing

CC-33A: -196 to 120 ºC

Fatigue lives at normal temperature (times)

1.2x107

timesI

Applicable linear expansion coefficients

5, 11, 16, 23, 27

I

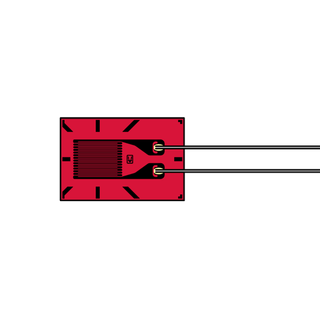

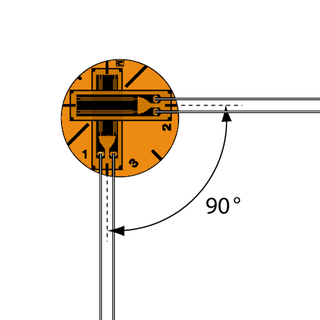

Biaxial stacked rosette 0°/90°

(350 Ohm)

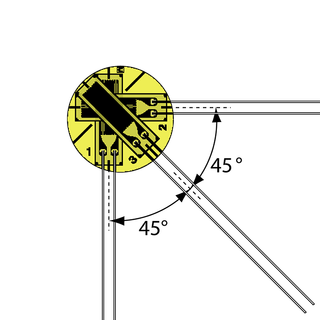

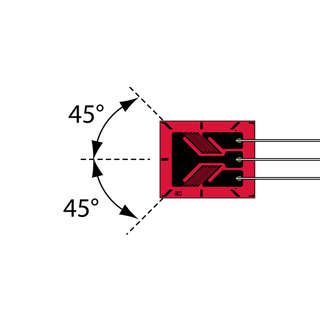

Triaxial stacked rosette 0°/45°/90°

(350 Ohm)

Products

We have many DMS in stock. For express delivery, please contact us by telephone.

1

Uniaxial(350 Ohm)

KFGS-1-350-C1-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

none

N10C2

N15C2

N30C2

N50C2

N1M2

L30C2R

L50C2R

L1M2R

L1M3R

L2M3R

L3M2R

L3M3R

L4M3R

L5M2R

L5M3R

3.4

3.4 mm

4.8

4.8 mm

2

2 mm

1

1 mm

Request

S

2

Uniaxial(350 Ohm)

KFGS-2-350-C1-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

none

N10C2

N15C2

N30C2

N50C2

N1M2

L30C2R

L50C2R

L1M2R

L1M3R

L2M3R

L3M2R

L3M3R

L4M3R

L5M2R

L5M3R

4.2

4.2 mm

6.3

6.3 mm

2

2 mm

2

2 mm

Request

S

3

Uniaxial(350 Ohm)

KFGS-3-350-C1-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

none

N10C2

N15C2

N30C2

N50C2

N1M2

L30C2R

L50C2R

L1M2R

L1M3R

L2M3R

L3M2R

L3M3R

L4M3R

L5M2R

L5M3R

4.2

4.2 mm

7.4

7.4 mm

2

2 mm

3

3 mm

Request

S

4

Uniaxial(350 Ohm)

KFGS-4-350-C1-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

none

N10C2

N15C2

N30C2

N50C2

N1M2

L30C2R

L50C2R

L1M2R

L1M3R

L2M3R

L3M2R

L3M3R

L4M3R

L5M2R

L5M3R

4.2

4.2 mm

8

8 mm

2

2 mm

4

4 mm

Request

S

5

Uniaxial(350 Ohm)

KFGS-5-350-C1-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

none

N10C2

L4M3R

L3M3R

L2M3R

L1M3R

L5M2R

L3M2R

L1M2R

N50C2R

N30C2R

N1M2

N50C2

N30C2

N15C2

L5M3R

4.2

4.2 mm

9.4

9.4 mm

2

2 mm

5

5 mm

Request

S

6

Biaxial stacked rosette 0°/90°(350 Ohm)

KFGS-1-350-D16-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

N10C2

N15C2

N30C2

N50C2

N1M2

L30C2S

L50C2S

L1M2S

L3M2S

L5M2S

L1M3S

L2M3S

L3M3S

L4M3S

L5M3S

none

8

8 mm Ø

1.8

1.8 mm

1

1 mm

Request

S

7

Biaxial stacked rosette 0°/90°(350 Ohm)

KFGS-2-350-D16-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

N10C2

N15C2

N30C2

N50C2

N1M2

L30C2S

L50C2S

L1M2S

L3M2S

L5M2S

L1M3S

L2M3S

L3M3S

L4M3S

L5M3S

none

10

10 mm Ø

2

2 mm

2

2 mm

Request

S

8

Biaxial stacked rosette 0°/90°(350 Ohm)

KFGS-3-350-D16-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

N10C2

N15C2

N30C2

N50C2

N1M2

L30C2S

L50C2S

L1M2S

L3M2S

L5M2S

L1M3S

L2M3S

L3M3S

L4M3S

L5M3S

none

10

10 mm Ø

2

2 mm

3

3 mm

Request

S

9

Biaxial stacked rosette 0°/90°(350 Ohm)

KFGS-5-350-D16-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

none

N10C2

L4M3S

L3M3S

L2M3S

L1M3S

L5M2S

L3M2S

L1M2S

L50C2S

L30C2S

N1M2

N50C2

N30C2

N15C2

L5M3S

11

11 mm Ø

2

2 mm

5

5 mm

Request

S

10

Triaxial stacked rosette 0°/45°/90°(350 Ohm)

KFGS-1-350-D17-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

N10C2

N15C2

N30C2

N50C2

N1M2

L30C2S

L50C2S

L1M2S

L3M2S

L5M2S

L1M3S

L2M3S

L3M3S

L4M3S

L5M3S

none

8

8 mm Ø

1.8

1.8 mm

1

1 mm

Request

S

11

Triaxial stacked rosette 0°/45°/90°(350 Ohm)

KFGS-2-350-D17-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

N10C2

N15C2

N30C2

N50C2

N1M2

L30C2S

L50C2S

L1M2S

L3M2S

L5M2S

L1M3S

L2M3S

L3M3S

L4M3S

L5M3S

none

10

10 mm Ø

2

2 mm

2

2 mm

Request

S

12

Triaxial stacked rosette 0°/45°/90°(350 Ohm)

KFGS-3-350-D17-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

none

N10C2

N15C2

N30C2

N50C2

N1M2

L30C2S

L50C2S

L1M2S

L1M3S

L2M3S

L3M2S

L3M3S

L4M3S

L5M2S

L5M3S

10

10 mm Ø

2

2 mm

3

3 mm

Request

S

13

Triaxial stacked rosette 0°/45°/90°(350 Ohm)

KFGS-5-350-D17-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

none

N10C2

L4M3S

L3M3S

L2M3S

L1M3S

L5M2S

L3M2S

L1M2S

L50C2S

L30C2S

N1M2

N50C2

N30C2

N15C2

L5M3S

11

11 mm Ø

2

2 mm

5

5 mm

Request

S

14

Biaxial 0°/90°(350 Ohm)

KFGS-2-350-D1-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

none

N15C2

N15C3

L1M2S

L1M3S

R1M2

R1M3

8.5

8.5 mm

10

10 mm

3

3 mm

2

2 mm

Request

S

15

Biaxial 0°/90°(350 Ohm)

KFGS-2-350-D2-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

6.8

6.8 mm

12

12 mm

4

4 mm

2

2 mm

Request

S

16

Biaxial 0°/90°(350 Ohm)

KFGS-2-350-D31-11

11 - Stahl

16 - Edelstahl

23 - Aluminiumlegierung

27 - Magnesiumlegierung

6.5

6.5 mm

10.5

10.5 mm

3

3 mm

2

2 mm

Request

S

D

CC-33A-5

Suitable for bonding general-purpose gages which are used for general stress

Request S

Suitable for bonding general-purpose gages which are used for general stress

Instantaneous strain gage adhesive cured at normal temperature.

Metals (Steel, stainless steel, copper, aluminum alloys A1050, A2024, etc.)

5 tubes á 2 grams

S

D

CC-35A-5

Instantaneous adhesive cured at normal temperatures for bonding to porous materials

Request S

Instantaneous adhesive cured at normal temperatures for bonding to porous materials

Suitable for bonding a gage to porous materials such as concrete for general stress measurement at normal temperatures of 20 to 80 °C

High viscosity makes it suitable for bonding to porous materials such mortar, lumber and concrete

Operating Temperature -30 to 120°C

S

D

CC-36-5

Instantaneous adhesive cured at normal temperatures for bonding a high-elonation gages

Request S

Instantaneous adhesive cured at normal temperatures for bonding a high-elonation gages

Suitable for bonding a high-elonation gage such as KFEM and KFEL at normal temperatures of 20 to 80°C

Suitable for bonding to hard-to-bond materials such as aluminum alloy (A7075) and magnesium alloy

High peeling resistance, high impact resistance and less aging deteriotation of bonding strength

Strong bonding power to hard-to-bond materials

Curing time is longer than CC-33A

Operating Temperature: -30 to 100°C

Main material:

Metals (Steel, stainless steel, copper, aluminum alloys A1050/A2024/A7075, magnesium alloy, etc.)

Plastics (acrylate, vinyl chloride, nylon, polypropylene, etc.)

Composite materials (CFRP, GFRP, printed board, etc.)

Concrete

Mortar

Lumber

Rubber

S

D

EP-340

Suitable for bonding gages for strain measurement at middle temperatures

Request S

Suitable for bonding gages for strain measurement at middle temperatures

Cured at normal temperatures or by heating

Operating Temperature -55 to 150°C

Ingredients 2 types of liquid mixed

Content 30 g (Main agent: 6 g × 4, Curing agent: 1.5 g × 4)

Main material: Metals (Iron, stainless steel, aluminum alloy, etc.)

S

D

PC-600

Non-Deleterious Phenol-Based Adhesive for low, middle and high temperatures and for bonding dages for transducers

Request S

Non-Deleterious Phenol-Based Adhesive for low, middle and high temperatures and for bonding dages for transducers

Suitable for strain measurement at low, middle and high temperatures and for bonding dages for transducers

Cured by heating

Operating Temperature -269 to 250°C

100g per Pack.

S