For a simple summing circuit with no trimming and no corner compensation, use the passive Load Cell Junction PCB, model JPP and for trimming and corner compensation, use the Active Junction Box, model JBA and for fault monitoring and fault detection alarm features, use the Load Cell Junction Box with Fault Monitoring LCI.

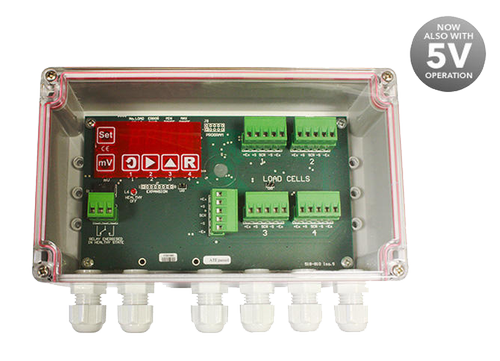

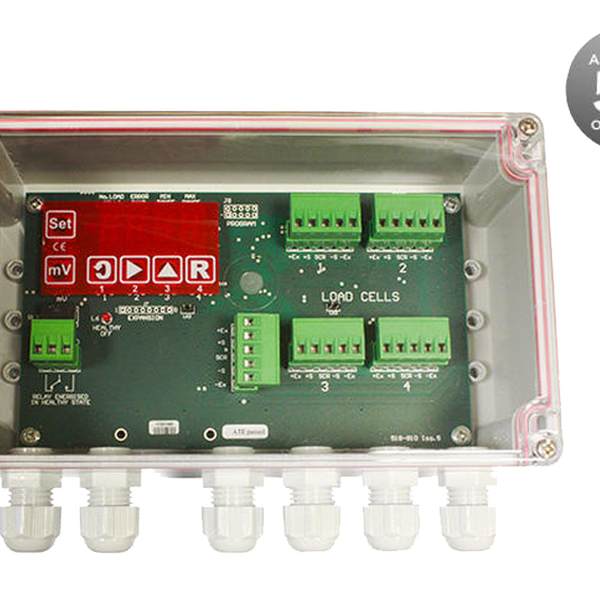

The LCI load cell failure alarm is designed to continuously monitor the condition of individual load cells and activates an alarm when faults in the system are detected, therefore providing increased safety and cost savings onsite for all weighing systems.

The latest version of the LCI now supports both 5V and 10V operation, 5V operation requires less power consumption from the connected instrument and simplifies barrier selection.

It provides protection for multi-load cell installations such as silos, tanks and other systems where the failure of an individual load cell can have serious consequences such as material shortage, overflow, or incorrect production batching. The device constantly samples the individual load cell channels and activates an alarm if any failure conditions are detected, ensuring a safe working system.

The LCI should be used in conjunction with a host intelligent weighing instrument such as Mantracourt’s ADW15, LCA20, LCD20, SMW etc. as well as suitable third-party products.

- Reduces down-time via immediate alarm and fault diagnosis

- Provides an assured working system in critical applications

- Avoids material shortage, overflow or incorrect batching from damaged load cells or cables

- Now supports both 5V and 10V operation - 5V operation requires less power from the

- connected instrument

- The alarm will be activated if:

- One or more load cells are out of balance

- Any load cell is operated outside a preset mV/V range

- Excitation voltage deviates from preset range

- Any connection is lost (open circuit detection)

- Any short circuit is detected

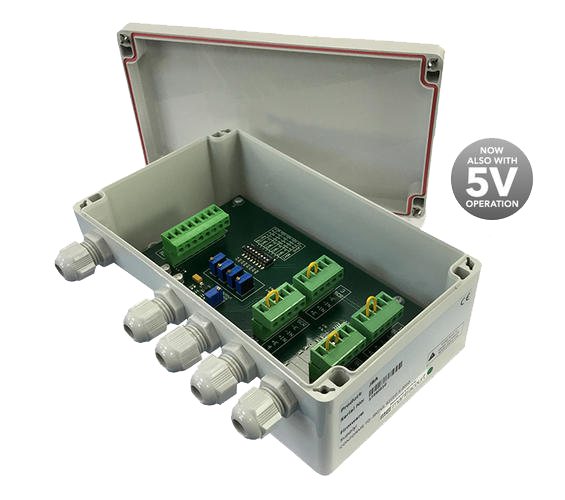

The JBA is an active summing junction box providing connectivity for up to four strain gauge-based sensors such as load cells, force sensors, pressure sensors, torque sensors etc. It derives its power from a host instrument such as the ADW, LCA20, LCD20.

Individual channel gains are setup via an 8-way DIP switch and multi-turn potentiometers to produce an overall 1:1 input/output gain e.g. if three gauges are connected, they are each given a gain of 0.33 so that when summed, the overall gain is unity. The whole installation then appears as a single gauge to the host.

Any resulting offset (Zero) is not adjustable but can be compensated for in the host instrument.

- Accurate and easy summation of up to 4 strain gauge load cells

- Corner correction enabled to compensate for manufacturing tolerances and loading in multiple strain gauge installations

- Individual gain adjustment provided for each channel

- Simplifies installation of multi-cell platforms, silos, tanks and hopper weighing systems

- Wide input range - from 0.5 to 20 mV/V

- No interaction between offset and gain

- No interaction between channels during calibration

- Waterproof to IP65 (NEMA4)

- Supplied pre-mounted in bulkhead housing (JBA as shown in main photo above), DIN rail mounted (D3) or PCB (JPA) version